5 Acoustic Guitar Fixes Using Super Glue

There are three or four different types of glue on your acoustic guitar right now, and one of them is super glue. While your acoustic guitar is a piece of woodworking mastery, and luthiers used refined techniques (and a host of tools!) to shape, bend, fit, and smooth those beautiful tone woods together... at the end of the day, the whole kit and caboodle is actually held together with glue.

First, A Little Background: Types of Glue Used in an Acoustic Guitar

Wood glue is used extensively on modern acoustic guitars to join wood-to-wood joints, such as joining the neck to the body, or binding, or sections of the body together.

Expanding wood glue is a popular choice by luthiers for the fretboard. The wood glue expands, filling cracks and crevices, firmly attaching the length of the fretboard to the neck.

Hide Glue is used more rarely on modern acoustics, but was the exclusive choice for early luthiers. So this glue is probably the only glue used if you own a vintage instrument. (Fun fact: hide glue often comes as small shavings of animal gelatin, which you have to heat with water yourself - you actually make the glue yourself!)

Super glue, surprisingly, is also used on acoustic guitar extensively. While super glue ranks right next to duct tape in the things-that-can-fix-anything-around-the-house category, it’s also helpful for guitars. Let’s take a look at how and why.

Wait, You Mean the Stuff At the Hardware Store?

Just to be clear, super glue is technically called “ethyl cyanoacrylate”, or just "cyanoacrylate”. Hence, the product names often include the letters “CA”, short for cyanoacrylate. We often see it in the store as Super Glue, Krazy Glue, Gorilla Glue, Hot Stuff, etc.

Super glue comes in a variety of viscosities, or thicknesses. We tend to think of those little super glue tubes we buy in the checkout aisle of the hardware store that I just mentioned. But, in fact, industrial grade super glues come in different sizes, viscosities, and even colors.

High quality super glues are also typically sold with applicators that attach to the nozzle. These applicators extend and narrow down so that you can apply the glue to very tiny, specific locations.

Why Super Glue for Acoustic Guitars?

Luthiers and guitar techs keep different types of glue on their bench for different reasons.

Super glue has gained in popularity because it has particular advantages:

- It holds strong

- It dries fast

- It dries clear

- It can wick into small cracks.

- It sands easily

Quick Note: When Not to Use Super Glue!

As we’re going to point out in a minute, super glue is good for SPECIFIC tasks in guitar assembly and repair. But it’s not good for everything.

Because super glue is so strong, it’s not a good choice for any wood-to-wood joints. It would never be used to attach the neck to the body, for example. Removing a piece of wood from another that has been super-glued together will pull bits (possibly quite big bits!) of the wood out.

It also shouldn’t be used with plastics. The interaction between the chemicals can cause damage to the guitar.

DISCLAIMER: This blog post is not a “how to”, but if you rush out to fix your guitar with super glue, remember:

- Work in a well-ventilated area. Asthma and breathing problems may arise in poorly-ventilated areas. An ideal place would be near an open window or in a porch.

- Wear safety glasses. Even a tiny drop splashing onto your eyes would be very dangerous.

- Open the container carefully and only after you are ready to work. Before opening it, hold it a safe distance from your face.

- Don’t wear cotton and wool. All product indications state this because cotton and wool clothing may react with cyanoacrylate and cause a fire.

- Wearing gloves is highly recommended. However, with or without gloves, never touch your face when you have glue on your fingers.

- Always have a good solvent near and ready. You will need to clean your fingers or quickly clean any surface that the super glue may splash out.

5 Acoustic Guitar Fixes Using Super Glue

1. Fretboard Cracks

Fretboards can crack along the length of the neck if they dry out too much. To avoid this, you can make sure you use fingerboard oil on it once a year. But if there is a crack, super glue can be used to fill in the crack.

For a few more details on this process, and some tips on how to match a rosewood fingerboard color, check out this Strange Guitarworks post.

Type of Super Glue: Medium CA Glue

2. Nut Placement

When seating the nut at the top of the fretboard, it’s helpful to use a little glue to keep it in place. This will keep it from moving, or falling out when you change strings.

If you’ve ever replaced the nut on your guitar, you may have experienced the same frustration I have: the previous person put glue on the BOTTOM of the nut. So when you remove the nut it tears bits of wood from the bottom of the groove. It’s better to seat the nut and then apply a drop of super glue to the FRONT of the nut, at the seam with the fretboard. For more details on that recommendation, see this article from Premier Guitar.

Type of Super Glue: Super Fast Thin Glue

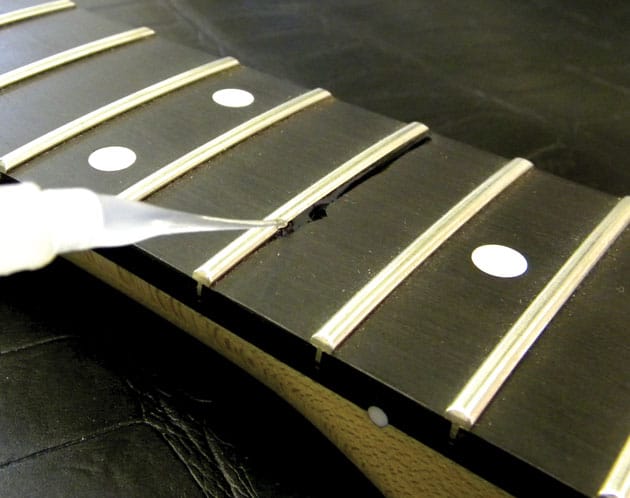

3. Fret Seating

Frets may pop up in response to heat and humidity changes, which can alternately shrink the wood, loosening the fret, and then expand the wood, squeezing the fret out of the groove. If a fret on the fingerboard pops up, it can be pressed down and held into place using a small amount of thin super glue.

Have some cotton swabs and razor blade handy so you can clean up the glue completely. For tips on the process, see this article.

Type of Super Glue: Super Fast Thin Glue

4. Inlay Repair

Inlays are typically thin and delicate, but need a very strong attachment to the guitar. Particularly on the fretboard and around the soundhole where your hands are constantly applying pressure, sweat, and heat. A very thin super glue is the perfect solution (pun intended).

For more details on fixing an inlay with super glue, check out this excellent walkthrough by Guitar Repair Bench.

Type of Super Glue: Super Fast Thin Glue

5. Filling in Chips

We're not talking about big chips here. But acoustic guitars often get small chips knocked off around the headstock or edges of the body. When this happens, it's rare to actually have the chip of wood to put back in. Usually it's a small, thin layer, and may even have been a series of small knicks that added up over time.

When this happens, you can actually fix this through a three-step process of: staining the exposed wood to the correct color, filling over it with super glue, and then sanding down to a smooth, matched finish.

For a nice walkthrough on this, see StewMac's tutorial.

Type of Super Glue: Medium CA Glue

Bonus: Accelerator

A super glue accelerator can be used with glues to make them dry faster. This is typically used with the heavier viscosity versions, or dyed versions, since these dry a bit slower.

An accelerator can also be used to prep a surface that may not bond as easily, or in cold and dry climates where bonding is slower.

An accelerator can also prevent the hazing that can happen when super glue's actually dry too fast.

Further Reading:

In addition to the recommended tutorial links listed above, here a few more articles that are helpful:

What is the Best type of Guitar Building Glue?

What Is The Best Glue For Guitar Building? (Luthier Glue Guide)